15° or 45° lead angle is recommended

Suitable for turning Ni-based super alloys, Co-based super alloys

Roughing and semi-finishing machining with continuous or light interruption

Type: CNGN, RCGX, RNGN, RPGN, RPGX, SNGN

–Suitable for machining nickel-based and cobalt-based superalloys and other difficult-to-machine materials.

–Metal removal rate is ten times higher than that of carbide inserts.

The heat generated during high-speed cutting softens the material being cut, thereby reducing the cutting force. Since Whisker-reinforced ceramic inserts can maintain high hardness at extremely high temperatures, can be used to machine superalloys and hard materials at high speeds. Whisker-reinforced ceramic inserts is suitable for turning Ni-based super alloys, Co-based super alloys and for roughing hard castings and hardened steel.

Nickel-Based Alloys | Inconel, Hastelloy, Haynes Alloys, Rene, Udimet, Waspaloy |

Weld Overlays | Stellite, Colmonoy, Inconel Weld |

Hardened Steels 45 Rc+ | Alloy Steels, Tool and Die Steels (H-13, D2, S7) |

Stainless Steels | 400 Series Stainless, 17-4 PH, 5-5 PH |

* High hadness (Hv 2, 100)

* Alumina substrate provides excellent oxidation resistance

* Silicon carbide whisker-reinforced ceramic offers high fracture toughness

* Excellent thermal shock resistance allows for machining with coolant and interrupted cutting

* Cutting speeds can be increased by 8-10 times compared to carbide tools, ideal for roughing and semi-finishing.

• High hardness and high fracture toughness levels

• Suitable for general turning and milling applications

• Ideal for machining Ni-based superalloys such as inconel, waspalloy, Rene

as well as hardened steels and castings at extremely high cutting speeds.

* Cutting speed (Vc) = 150-450 m/min

* Feed rate (f) = 0.1-0.2 mm/rpm

* Depth of cut (Ap) = 0.5-3 mm

* Cooling method: Dry and wet

|  | ||

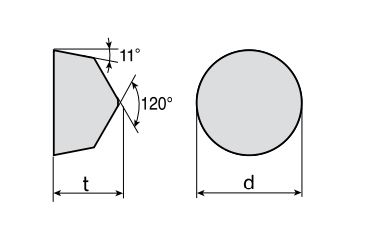

ISO Number | d (inch) | t (inch) | r (inch) |

CNGN 120408 T6 | 0.500 | 0.187 | 0.031 |

CNGN 120412 T6 | 0.500 | 0.187 | 0.047 |

CNGN 120708 T6 | 0.500 | 0.312 | 0.031 |

CNGN 120712 T6 | 0.500 | 0.312 | 0.047 |

|  | |

ISO Number | d (inch) | t (inch) |

RCGX 090700 | 0.375 | 0.315 |

RCGX 120700 | 0.500 | 0.315 |

|  | |

ISO Number | d (inch) | t (inch) |

RNGN 090300 | 0.375 | 0 .125 |

RNGN 120400 | 0.500 | 0 .187 |

RNGN 120700 | 0.500 | 0 .312 |

RNGN 190700 | 0.750 | 0 .312 |

|  | |

ISO Number | d (inch) | t (inch) |

RPGN 120400 | 0.500 | 0.187 |

|  | |

ISO Number | d (inch) | t (inch) |

RPGX 090700 | 0.375 | 0.312 |

RPGX 120700 | 0.500 | 0.312 |

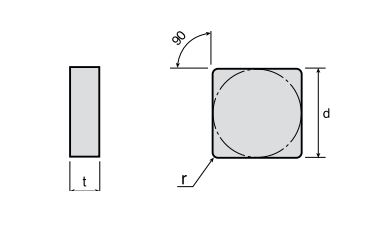

|  | ||

ISO Number | d (inch) | t (inch) | r(inch) |

SNGN 120408 | 0.500 | 0.187 | 0.031 |

SNGN 120412 | 0.500 | 0.187 | 0.047 |

SNGN 120708 | 0.500 | 0.312 | 0.031 |

SNGN 120712 | 0.500 | 0.312 | 0.047 |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]