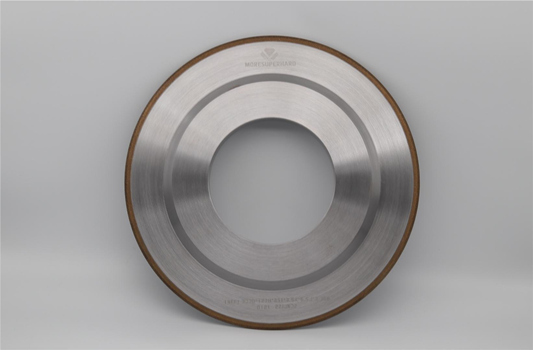

Roll grinding wheel

Diamond & CBN grinding wheel for roller process

* Diamond Grinding Wheel used for WC hard alloy roll ring process.

* CBN Grinding Wheel used for HSS Roller process.

* Hole-shape Grinding Wheel: for roll ring notch and finishing.

* Ex-circle grinding Wheel: for ex-circle grinding and cutting of roll ring.

* Inverted-angle Grinding Wheel: for inverted-angle of roll ring.

Diamond and CBN grinding wheel for Roll grinding

Moresuperhard can provide completed grinding solution for roll industry, including resin / metal /electroplated diamond & CBN grinding wheel for cylindrical grinding and groove grinding of roll.

Grinding machine:

Moresuperhard electroplated/metal diamond grinding wheel for roll can match various brand roll ring cylindrical grinding machine and cylindrical grinder, such as DKD,Herkules, Valmetetc,Wendt,etc.

External Grinding Carbide Roll, Resin diamond grinding wheel for HVOF carbide coating

OD resin bond diamond grinding wheel for grinding and finishing of thermal spray coatings ( including tungsten carbide , chrome carbide and chrome oxide ), ceramics, carbides, chilled iron composites and other hard-to-grind materials.

Diamond sanding belt for polishing roll

Diamond sanding abrasive belt is divided into metal nickel plating electroplated bond and resin bond, a resin bond also consists of flexible and hard type.

PCD Notching Tools For TC Roll Cutting

The PCD Notching Tools are applied for notching (milling) of hard-to-machine materials with high processing and high work efficiency.

PCBN inserts for roll industry

CBN is a super-hard material that is second only to diamond in terms of hardness,CBN cutting tools are widely used for the continuous cutting of high-hardness and hard-to-machine materials.

Solid CBN inserts have great advantage in processing all ferrous materials, is ideal for machining Cast Iron( Gray Iron, Ductile Iron, Chilled Cast Iron, High Chromium Cast Iron, Alloy Wear-resistant Cast Iron, etc.),Hard Steel (Harden Steel, Bearing Steel, Die Steel, High Mn Steel, Hig-speed Steel, etc.), and Tungsten Carbide.

Type: RNMN,RCGX, SNMN

Solid CBN insert for roll

![]()

Type | L | ΦI.C | S | R | Standard chamfer | Corresponding tool holder |

RNMN060400 | - | 6.35 | 4.76 |

S01020 S01025 S02020 S02030 S05020 S10020 |

CRGBR/LCRDNN | |

RNMN090300 | - | 9.525 | 3.18 | |||

RNMN090400 | - | 9.525 | 4.76 | |||

RNMN090700 | - | 9.525 | 7.94 | |||

RNMN120400 | - | 12.7 | 4.76 | |||

RNMN120600 | - | 12.7 | 6.35 | |||

RNMN120700 | - | 12.7 | 7.94 | |||

RNMN150700 | - | 15.875 | 7.94 | |||

RNMN200800 | - | 20 | 8 | |||

RNMN201000 | 20 | 10 | ||||

RNMN251000 | 25.4 | 10 | ||||

RNMN251200 | 25.4 | 12 |

Type of tool holder | Dimension | Matched insert | |||

h1=h2 | L2 | b | L1 | ||

CSSNR/L2020M09 | 20 | 30 | 20 | 150 | SNMN09 |

CSSNR/L2525M12 | 25 | 30 | 25 | 150 | SNMN12 |

CSSNR/L3232P12 | 32 | 35 | 32 | 170 | SNMN12 |

CSSNR/L4040S15 | 40 | 38 | 40 | 250 | SNMN15 |

CSSNR/L5050T20 | 50 | 38 | 50 | 300 | SNMN20 |

Type

| Dimension | ||||

L | ΦI.C | S | r | Standard Chamfer | |

SNMN090304 | 9.525 | 9.525 | 3.18 | 0.4 |

S01020 S01025 S02020 S02030 S05020 S10020 |

SNMN090308 | 9.525 | 9.525 | 3.18 | 0.8 | |

SNMN090312 | 9.525 | 9.525 | 3.18 | 1.2 | |

SNMN090404 | 9.525 | 9.525 | 4.76 | 0.4 | |

SNMN090408 | 9.525 | 9.525 | 4.76 | 0.8 | |

SNMN090412 | 9.525 | 9.525 | 4.76 | 1.2 | |

SNMN120404 | 12.7 | 12.7 | 4.76 | 0.4 | |

SNMN120408 | 12.7 | 12.7 | 4.76 | 0.8 | |

SNMN120412 | 12.7 | 12.7 | 4.76 | 1.2 | |

SNMN120712 | 12.7 | 12.7 | 7.94 | 1.2 | |

SNMN120716 | 12.7 | 12.7 | 7.94 | 1.6 | |

SNMN150716 | 15.875 | 15.875 | 7.94 | 1.6 | |

SNMN201020 | 20 | 20 | 10 | 2.0 | |

Type | Dimension | Matched insert | |||

h1=h2 | L2 | b | L1 | ||

CSSNR/L2020M09 | 20 | 30 | 20 | 150 | SNMN09 |

CSSNR/L2020M12 | 25 | 30 | 25 | 150 | SNMN12 |

CSSNR/L2020P12 | 32 | 35 | 32 | 170 | SNMN12 |

CSSNR/L2020S15 | 40 | 38 | 40 | 250 | SNMN15 |

CSSNR/L2020T20 | 50 | 38 | 50 | 300 | SNMN20 |

Type | Dimension | ||||

L | ΦI.C | S | r | Standard Chamfer | |

RCMN060400 | 6.35 | 4.76 |

S01020 S02020 S05020 S10020 | ||

RCMN090400 | 9.525 | 4.76 | |||

RCMN090700 | 9.525 | 7.94 | |||

RCMN120700 | 12.7 | 7.94 | |||

RCMN150700 | 15.875 | 7.94 | |||

RCMN190700 | 19.05 | 7.94 | |||

Type | Dimension | Matched insert

| |||

h1=h2 | L2 | b | L1 | ||

CRDCN2020M09 | 20 | 30 | 20 | 150 | RCMN09 |

CRDCN2525M12 | 25 | 30 | 25 | 150 | RCMN12 |

CRDCN3232P12 | 32 | 35 | 32 | 170 | RCMN12 |

CRDCN4040S15 | 40 | 38 | 40 | 250 | RCMN15 |

CRDCN5050T15 | 50 | 38 | 50 | 300 | RCMN15 |

Type | Dimension | Standard Chamfer | |||

L | ΦI.C | S | r | ||

RCMX060400V | 6.35 | 4.76 | 0.8 | - | S01020 S02020 S03020 S05020 S10020 S20020 |

RCMX060500V | 6.35 | 5.56 | 0.8 | - | |

RCMX060600V | 6.35 | 6.35 | 0.8 | - | |

RCMX090700V | 9.525 | 7.94 | 1 | - | |

RCMX090700V | 12.7 | 7.94 | 2 | - | |

RCMX151000V | 15.875 | 10 | 2 | - | |

RCMX191000V | 19.05 | 10 | 2 | - | |

RCMX201200V | 20 | 12 | 2 | - | |

RCMX251200V | 25.4 | 12 | 2 | - | |

Type | Dimension | Matched insert | |||

h1=h2 | L2 | b | L1 | ||

CRDCN2020M06 | 20 | 30 | 20 | 150 | RCMX06 |

CRDCN2525M09 | 25 | 30 | 25 | 150 | RCMX09 |

CRDCN3232P12 | 32 | 35 | 32 | 170 | RCMX12 |

CRDCN4040S15 | 40 | 38 | 40 | 250 | RCMX15 |

CRDCN5050T20 | 50 | 38 | 50 | 300 | RCMX20 |

Inserts type | Dimension | Standard Cutting Edge | |||

L | ΦI.C | S | r | ||

RCMX060400Y | 6 | 6.35 | 4.76 | 0.6 |

S02020 S05020 S10020 |

RCMX060500Y | 6 | 6.35 | 5.0 | 0.6 | |

RCMX060700Y | 6 | 6.35 | 7.94 | 0.6 | |

RCMX090700Y | 9 | 9.525 | 7.94 | 1 | |

RCMX120700Y | 12 | 12.7 | 7.94 | 1.2 | |

RCMX191000Y | 19 | 19.05 | 10.0 | 1.2 | |

RCMX251200Y | 20 | 20 | 12.0 | 1.2 | |

Type | Dimension | Matched insert | |||

h1=h2 | L2 | b | L1 | ||

CRDCN2020M06 | 20 | 30 | 20 | 150 | RCMX06 |

CRDCN2020M09 | 25 | 30 | 25 | 150 | RCMX09 |

CRDCN2020P12 | 32 | 35 | 32 | 170 | RCMX12 |

CRDCN2020S15 | 40 | 38 | 40 | 250 | RCMX15 |

CRDCN2020T20 | 50 | 38 | 50 | 300 | RCMX20 |

PCD Round Inserts for machining roll

PCD bottom flat carving cutter