Diamond tools are used in the grinding, finishing, super finishing, polishing and edge grinding processes of optical elements. Moresuperhard can provide diamond cutting wheel, metal diamond plain grinding wheel, spherical diamond grinding wheels, diamond finish pellet (column) and diamond super finish pellet(column),diamond edge grinding wheel, diamond Profile grinding wheel,etc...

Diamond Cut off Wheels

Diamond cut off wheel is an ideal tool for cutting optical elements,and has high efficiency and good incision. The main types of saw blade are diamond cutting wheel and diamond dicing blade.

Diamond Milling Grinding Wheel

Optical diamond milling tools are used for grinding and finishing of optical lens edge and surface. Diamond milling grinding wheels grind the optical elements blanks to form optical elements prototypes with certain geometric shape, dimensional accuracy and surface roughness.

Diamond grinding wheels are divided into flat diamond grinding wheels and spherical diamond grinding wheels.

Flat diamond milling grinding wheel

Flat diamond milling grinding wheel is used for rough and finish grinding lens, prisms, and other optical glass.

Product Name | Specification(mm) | Hole Diameter(mm) | Grit(#) |

Flat Diamond Grinding Wheel | 250, 300, 350, 400, 450, 480, 500 | 146, 230, 250, 360, 370 | 60/70-325/400 |

Sphere diamond milling grinding wheel

Sphere diamond milling grinding wheel is used for spherical grinding and chamfering such as optical lens, optical glass, and etc.

Product Name | Specification(mm) | Grit | Connector |

Sphere Diamond Milling Grinding Wheel | 3-300 | 30/35-325/400 | Upon request |

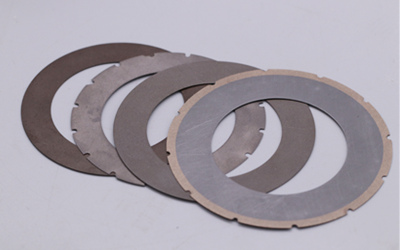

Diamond finish pellet (column) and diamond super finish pellet(column)

Diamond finish pellets(columns) are mainly used for removing the damage layer and rough surface left by previous process, to ensure that optical elements have a certain size and machining margin.

Diamond super finish pellets(columns) are mainly used for removing the damage layer (rough surface) left by previous process, improving the shape and surface dimension, roughness and aperture value of optical elements.

Product Name | Specification | Grit | Concentration | Radius | |

Diameter(mm) | Thickness(mm) | ||||

Diamond finish pellet | Φ3-Φ20 | 2.5-10 | 180#-2000# | 75%-150% | Upon request |

Diamond super finish pellet | Φ3-Φ20 | 2.5-10 | 800#-3000# | 75%-150% | |

Polishing pellet | Φ3-Φ20 | 2.5-10 | |||

Diamond edge grinding wheel

Edge grinding wheels usually consist of metal, resin and electroplated diamond grinding wheels. Electroplated bond edge grinding wheel, which has high precision and good sharpening, can be used for shaping, forming, and grinding not only a variety of optical lenses and glasses but also gemstones, semiconductors, tungsten carbide.

Optical elements are ground vertically, parallel, obliquely and molding.

Diamond edge grinding wheels are mainly used for removing the burrs, chips, thickness tolerance of optical elements excircle.

Diamond Profile grinding wheel

Used for profile milling and edge grinding for optical glass and lens.

Product Name | Diameter(mm) | Grit | Hole |

Sintered metal profile grinding wheel | 100-400 | 100#-800# | 22, 25, 30, 31.75, 32, 75, 127, 203 |

Electroplated edge grinding wheel | Φ125, 150, 160, 180, 200 | 100#-800# | 22, 30, 31.75, 32 |