More SuperHard has been present on the natural diamond processing polishing industry for over 10 years. We provide the natural diamond cutting ,bruting , girdling and polishing solution and service. The natural diamond tools range offered by More SuperHard, diamond rotary cutting disc and diamond saw blades, diamond bruting wheels ,diamond laps grinding disc, mono crystal diamond tools etc. MORE® diamond tools have enjoyed wide popularity in South Africa, Belgium, Namibia, Hong Kong, India , Israel and others Jeweler processing market.

"Diamonds are forever, one is forever". When this slogan was first proposed by De Beers, diamonds were given the meaning of love. The hardness and sparkle of diamonds represent the eternity and romance of love. However, where does a radiant diamond ring come from? Today Moresuperhard will take a look at the journey of a diamond from mining, to cutting, bruting and polishing.

1. Formation of Diamonds

The formation of diamonds is formed by the melting and crystallization of primitive carbon at high temperature and high pressure in geological layers hundreds of kilometers deep underground. Most of the primary diamond mines are attached to mica peridotite. Magma erupted to the subsurface.

2. Mining Diamond

At present, diamond mines are found in Australia, the United States, Africa, and Russia. Only about 20% of the diamonds mined in the world are of gem quality. So how are diamonds mined? There are currently four mining methods, of which the most commonly used is open-pit mining,

Underground mining, Open pit mining, Alluvial mining, Ocean mining.

3. Cutting Diamond

There are three main cutting techniques for rough stones: splitting, sawing and laser cutting. The current mainstream is sawing and laser cutting.

The sawing method is to use a phosphor bronze blade, apply diamond powder to the edge of the blade, and cut along the cutting plane, and each carat needs to go through a 4-6 hour cutting process.

Laser cutting method is the most common cutting method now, laser cutting has higher accuracy, higher cutting efficiency and less loss of diamonds.

4. Bruting Natural Diamond

The cut diamond needs to be edged and shaped, and the diamond will be polished into round, heart, oval, emerald or other special shapes according to the designed plan. The bruting of the diamond is very important in diamond processing. Steps, because the quality of the girdle polishing effect largely determines the size and fire grade of the diamond.

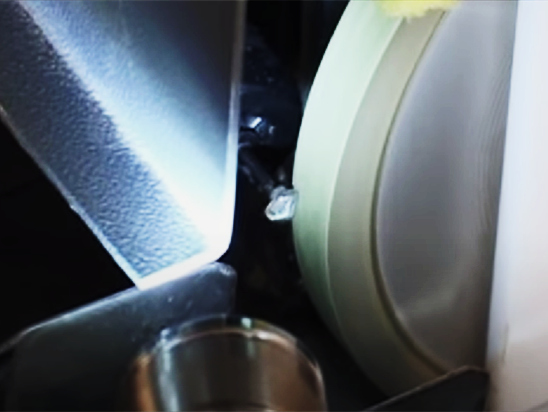

Diamond grinding, bruting uses a ceramic diamond grinding wheel. This process has high requirements for the radial runout of the grinding wheel, the sharpness and shape retention of the grinding wheel. If it is not enough, the processing efficiency will be greatly reduced. Therefore, a good diamond is often inseparable from a good diamond bruting wheel. Moresuperhard ceramic diamond grinding wheels are mainly used for grinding the girdle of natural diamonds. Due to its good sharpness and unique self-sharpening, it can complete the high-efficiency grinding of the diamond girdle without easily causing the diamond to crack and break

Bruting and Girdling Natural Diamond

Bruting gives the diamond its basic shape. The main tools used in bruting are diamond bruting wheels and CNC bruting machine (such as EOS bruting machine) .Our diamond bruting & girdling wheels are divided into

* MD-20: Fine Polishing

* MD-40 / MD-60: Rough Polishing

* MD-80: Rougher Polishing

5. Polishing Natural diamond

The polishing of a diamond is the last stop of the diamond before it reaches your finger. On a cast iron disc coated with diamond powder and lubricant, all facets are polished, which is also a key step in the diamond's alluring brilliance. First grind 8 large faces on the bottom surface, then make 16 facets, plus the pointed bottom, a total of 25 facets, and then extend the triangular facets, the kite face and the facet on the waist, a total of 33 facets , such a round diamond has 58 facets. These 58 facets directly affect the quality of the diamond cut, so the most standard proportion of diamond cut within a certain value range is called "perfect cut" . Such diamonds can release the most dazzling light!

Polishing gives the diamond entire process and to make diamond sparkle. MORE SUPERHARD diamond grinding discs are used for polishing faceting gemstones (Jade, Crystal, Agate) spinel, sapphire and jewellery, etc.

The diamond grinding discs are divided into resin diamond discs and electroplated diamond flat lap discs. The grain size of diamond disc up to 15000#.

Application cases of diamond polishing

Finally, add a delicate setting to the tortured diamond, and it has finally completed its difficult journey, hugging tightly around your ring finger.