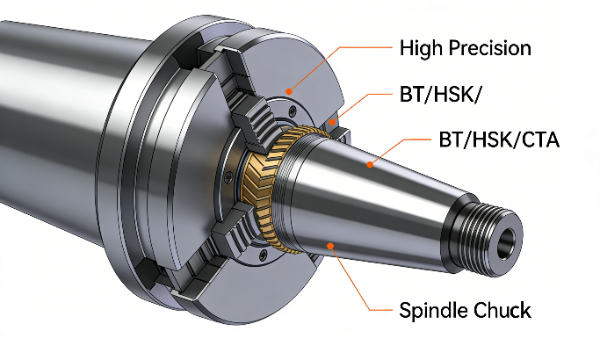

In the field of high-precision CNC machining, tool holders are the crucial link connecting the spindle and the cutting tool, and their performance directly impacts the accuracy and efficiency of the entire machining process. If the tool holder exhibits excessive radial runout or insufficient rigidity, it will directly affect the tolerance accuracy of the parts, resulting in parts that do not meet design requirements. Simultaneously, it will increasemachining cycle times, reduce production efficiency, shorten tool life, and increase production costs for the company.

Given the importance of tool holders, this article will focus on how to selct the ideal tool holder for high-precision machining needs, particularly focusing on the three widely used tool holder systems in the industry: BT, HSK, and CTA. This will help machining companies and technicians make more informed choices.

BT tool holders utilize a symmetrical taper design. This structure allows them to maintain good stability in medium-to-high speed machining environments, making them widely used in milling and drilling processes. Their advantages include a relatively simple structure, affordable cost, and good versatility, compatible with various types of CNC machine tools. However, their performance is slightly inferior to HSK and CTA tool holders in ultra-high-speed machining scenarios.

HSK tool holders employ a unique dual-contact design, where both the tapered surface and the flange surface make contact. This design significantly improves the rigidity and balance of the tool holder, resulting in excellent performance in high-speed machining. It effectively reduces vibrations generated during high-speed rotation, ensuring machining accuracy, and also features quick tool change capabilities, contributing to improved production efficiency. HSK tool holders are suitable for applications requiring high machining accuracy and speed, such as aerospace component machining and precision mold machining.

CTA tool holders are renowned for their ultra-high concentricity and exceptional balance. Their radial runout is typically controlled within 1 μm, giving them an irreplaceable advantage in micro-milling and precision finishing. In scenarios involving the machining of small parts or parts requiring extremely high surface quality, CTA tool holders ensure stable operation of the cutting tool, resulting in high surface finish and precise dimensional accuracy.

Summary of Applications, Advantages, and Machine Tool Compatibility of the Three Tool Holder Systems

Type | Introduction | Advantages | Disadvantages |

BT | The BT tool holder is the most common spindle taper standard in Asia and Europe. It features a symmetrical V - shaped flange design, which provides better balance at high speeds. It only contacts the spindle through the taper surface and belongs to a single - sided positioning system. Common specifications include BT30, BT40, and BT50, which are widely used in traditional machining scenarios. | Symmetrical design with good balance. Stable in heavy - cutting operations. Widely used in Asia and Europe. | When the rotational speed exceeds 10,000 rpm, the centrifugal force will cause the spindle hole to expand, and the tool holder will be pulled deeper into the spindle, leading to tool position deviation and reduced accuracy. Therefore, it is not suitable for ultra - high - speed machining. |

CAT | Also known as V - flange or Caterpillar taper shank, it is the main spindle taper standard in North America. | Robust and durable, highly suitable for heavy - duty machining. | Asymmetrical flange leads to poor balance at high speeds. |

HSK | The HSK toolholder comes in various specifications, such as Type A, B, C, D, E, and F. Type A has a drive slot (capable of transmitting relatively large torque and suitable for some heavy - cutting operations), while Type E does not (more suitable for high - speed machining). | It features double contact (taper surface + face), ensuring high precision and excellent performance at high speeds with minimal run - out. | It has a relatively high cost and requires a dedicated HSK spindle. |

Radial Runout

In high-precision CNC machining, radial runout is one of the important indicators for measuring the accuracy of the tool holder, and the radial runout value is usually required to be less than 3μm. Excessive radial runout can cause the cutting tool to deviate during rotation, thus affecting the machining accuracy of the part, leading to dimensional errors and excessive surface roughness.

Different types of tool holders perform differently in terms of radial runout control. BT tool holders can meet the radial runout requirements of general high-precision machining; HSK tool holders, due to their dual-contact design, are even better in radial runout control; while CTA tool holders can achieve radial runout within 1μm, making them particularly suitable for micro-machining scenarios with extremely high precision requirements.

The balance of the tool holder directly affects the vibration during the machining process. Good balance reduces the centrifugal force generated during high-speed rotation, reduces vibration, thereby improving machining accuracy and surface quality, and extending the service life of the tool and machine tool.

BT tool holders have stable balance and can meet the needs of medium and high-speed machining; HSK tool holders, with their dual-contact structure, have better balance during high-speed rotation, effectively avoiding machining errors caused by vibration; CTA tool holders fully consider balance in their design, maintaining stable operation even in high-precision machining such as micro-milling.

The rigidity of the tool holder is a key factor in ensuring the stability of the machining process. Insufficient rigidity will cause the holder to deform under the action of cutting forces, thereby affecting the cutting trajectory of the tool, reducing machining accuracy, and even potentially causing safety accidents such as tool breakage.

The dual-contact design of HSK tool holders gives them extremely high rigidity, allowing them to withstand large cutting forces, suitable for heavy milling and hard material processing; BT tool holders also have a certain degree of rigidity, meeting the needs of conventional machining; although CTA tool holders focus more on high precision and balance, their rigidity can also meet the requirements of machining processes such as micro-milling, ensuring the stability of the machining process. The right tool holder can effectively reduce vibration, improve the surface finish and quality of parts, reduce tool wear, extend tool life, save production costs, and increase production efficiency for businesses.

In high-speed finishing, high demands are placed on the balance and thermal stability of the tool holder.

HSK tool holders, with their excellent dual-contact design, possess superior balance and thermal stability, maintaining stable operation at high rotational speeds and effectively guaranteeing machining accuracy;

CTA tool holders are known for their ultra-high concentricity and balance, exhibiting excellent performance in high-speed finishing, especially suitable for applications requiring extremely high precision.

Therefore, HSK or CTA tool holders are preferred for high-speed finishing.

Heavy milling and hard material machining require tool holders with strong clamping force and rigidity to withstand large cutting forces.

BT tool holders have good clamping performance and a certain degree of rigidity, meeting the needs of conventional heavy milling and hard material machining;

HSK tool holders, due to their dual-contact design, have greater rigidity and clamping force, making them more suitable for heavy milling and hard material machining scenarios with high difficulty and large cutting forces. Therefore, BT or HSK tool holders can be selected for this type of machining.

Micro-milling, mold finishing, and thin-walled part machining require extremely high concentricity of the tool holder, ensuring precise positioning and stable operation of the cutting tool.

CTA tool holders offer extremely high concentricity (typically meeting the demands of high-precision machining applications), resulting in parts with high dimensional accuracy and excellent surface quality.

Therefore, CTA tool holders are an ideal choice for micro-milling, mold finishing, or thin-walled part machining.

Furthermore, when selecting a tool holder, factors such as tool diameter, overhang length, and cutting load must be considered. For smaller tool diameters, higher concentricity is required, making CTA tool holders a preferred choice;

For longer overhang lengths, the rigidity and stability of the tool holder are more important, and HSK tool holders may be a better option; for larger cutting loads, a rigid tool holder with high clamping force, such as an HSK or BT tool holder, is necessary.

BT Taper: The BT taper series includes models such as BT30, BT40, and BT50, offering good versatility and widely used in various milling centers.

Different BT taper models are suitable for different specifications of machine tools and processing needs. BT30 is suitable for small machining centers, mainly used for processing small parts;

BT40 is the most widely used model, suitable for medium and large machining centers, and can meet most conventional processing needs; BT50 is suitable for large machining centers, used for heavy milling of large parts, etc.

The HSK taper series includes types such as HSK-E, HSK-F, and HSK-A. Its design features enable it to support ultra-high-speed machining, rapid tool changes, and good thermal stability.

HSK-E type is suitable for high-speed machining, with a maximum speed of over 40000 r/min; HSK-F type is mainly used for medium speed and medium cutting force machining;

HSK-A type is suitable for high rigidity, high speed, and high cutting force machining scenarios, such as precision machining in the aerospace field.

CTA tool holders are mainly compatible with high-precision spindle systems. Their taper design ensures precise matching with the spindle, achieving ultra-high concentricity and stability, meeting the needs of high-precision machining. They are usually used in precision machining equipment equipped with high-precision spindles.

Balancing Grade:

The balancing grade of the tool holder directly affects the vibration during the machining process and the machining accuracy. When selecting, the appropriate balancing grade should be chosen according to the machining speed and accuracy requirements. High-speed machining and high-precision machining usually require a higher balancing grade, such as G2.5 or G1.0.

Coolant-through Capability:

Tool holders with coolant-through capability can deliver coolant directly to the cutting area, effectively reducing cutting temperature, reducing tool wear, and improving machining efficiency and surface quality. When machining difficult-to-machine materials such as high-temperature alloys and stainless steel, internal cooling is particularly important; therefore, tool holders with internal cooling capabilities should be prioritized.

Vibration resistance:

Tool holders with good vibration resistance can reduce vibrations during machining, ensuring machining accuracy and surface quality, and extending tool life.

When choosing a tool holder, consider its structural design and material properties. For example, the dual-contact design of HSK tool holders provides excellent vibration resistance.

Tool holder length: The length of the tool holder affects the tool overhang length, which in turn affects the rigidity and stability of the machining process. When selecting a tool holder, choose one with an appropriate length based on the structure of the workpiece and the machining process requirements, minimizing the tool overhang length to improve machining rigidity.

---EDITOR:Doris Hu,Penny Xu

---POST:Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]