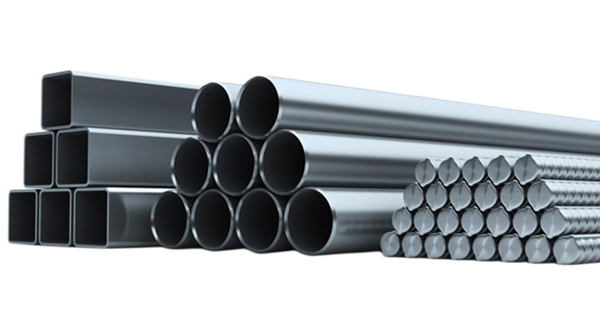

What is stainless steel ?

According to the definition of GB/T20878-2007, stainless Steel is stainless, corrosion resistance as the main characteristics, and chromium content of at least 10.5%, the maximum carbon content is not more than 1.2% of Steel.

Stainless Steel is the abbreviation of Stainless acid Steel, air, steam, water and other weak corrosion medium or Stainless Steel called Stainless Steel. And the chemical corrosion resistant medium (acid, alkali, salt and other chemical corrosion) corrosion of steel called acid steel.

Stainless steel is often divided into martensitic steel, ferrite steel, austenitic steel, austenite-ferrite (duplex) stainless steel and precipitation hardening stainless steel. In addition, can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel.

Due to the difference in chemical composition, the former is not necessarily resistant to chemical media corrosion, while the latter generally have no rust. The corrosion resistance of stainless steel depends on the alloying elements contained in the steel.

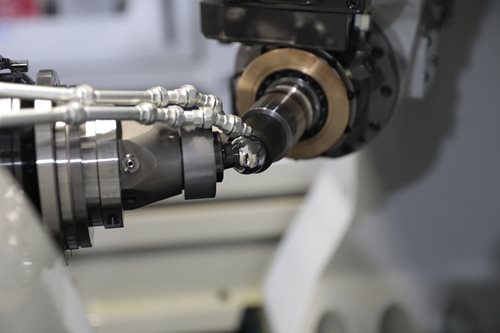

How to choose the grinding wheel for grinding stainless steel?

(1) Abrasive

White corundum (WA) is suitable for grinding martensite and martensite + ferrite stainless steel due to its good cutting performance and self-sharpening performance, sharp grinding wheel, small chip deformation, low grinding force and grinding temperature. Single crystal corundum is hexagonal single crystal, the abrasive grain is spherical polyhedral polyhedron, the cutting edge strength and toughness is high, suitable for grinding austenite and austenite + ferrite stainless steel. The hardness of CBN (cubic boron nitride) abrasive is second only to that of diamond (HVI0000). It has good chemical stability, does not affinity with iron group elements, does not oxidize at (1300~1500)℃, and the grinding edge tip is not easy to become blunt, so the grinding force and grinding heat are low. High grinding surface quality, suitable for grinding all kinds of stainless steel.

(2) Granularity

When grinding stainless steel, the abrasive debris is easy to adhere to and block the surface of the grinding wheel. Therefore, the grinding wheel with slightly coarser grain size should be selected when grinding the general steel.

(3) Bond

The grinding wheel for grinding stainless steel requires high strength to withstand large loads. Ceramic bond is heat resisitant, corrosion resisitant, not afraid of moisture, porous not only can maintain the grinding performance of the grinding wheel, but also has high productivity, suitable for the production of stainless steel grinding wheel bond. Resin binder can also be used to make grinding wheel when grinding the inner hole of acid resistant stainless steel, which can reduce the roughness of grinding surface.

(4)Hardness

When grinding stainless steel, THE grinding wheel is easy to become blunt due to the material properties and grinding characteristics, so the hardness of grinding wheel should be lower than that of grinding ordinary steel, so that the grinding wheel can obtain self-sharpening. However, the hardness of the grinding wheel should not be too low. If the grinding wheel is too low, the grinding wheel detachments too fast, resulting in the reduction of grinding ratio and poor shape retention of the grinding wheel.

Problems prone to occur in the grinding stainless steel process:

1. Stainless steel toughness, high thermal strength, and the grinding wheel grinding grain cutting edge has a larger negative front Angle, grinding debris is not easy to be cut off, cutting resistance, extrusion, friction is intense. The grinding force per unit area is large, and the grinding temperature can reach 1000℃ ~ 1500℃. At the same time, under the action of high temperature and high pressure, the chip is easy to adhere to the grinding wheel and fill the gap of the abrasive particles, so that the abrasive particles lose their cutting effect. The type of stainless steel is different, the grinding wheel clogging situation is not the same, such as the grinding of concentrated nitric acid resistant stainless steel and heat resistant stainless steel, adhesion, clogging phenomenon is more serious than 1Cr18NiTi, and 1Cr13, 2Cr13 and other martensitic stainless steel is lighter.

2. The thermal conductivity of stainless steel is small, the high temperature of grinding is not easy to be derived, the workpiece surface is easy to produce burns, annealing and other phenomena, annealing layer depth can sometimes reach 0.01 ~ 0.02 mm. Severe extrusion deformation occurs during grinding process, which leads to work hardening of the grinding surface. Especially when grinding austenitic stainless steel, martensite structure is easy to be formed after grinding because the austenitic structure is not stable enough.

The linear expansion coefficient of stainless steel is large, it is easy to deform under the action of grinding heat, and its size is difficult to control. Especially thin wall and slender parts, this phenomenon is more serious.

3. Most types of stainless steel can not be magnetized, in the plane grinding, can only rely on mechanical clamping or special fixture to hold the workpiece, the use of workpiece side clamping workpiece, deformation and cause shape or size error, sheet workpiece is more prominent. At the same time, it will cause chatter in the grinding process and appear scaly corrugated.

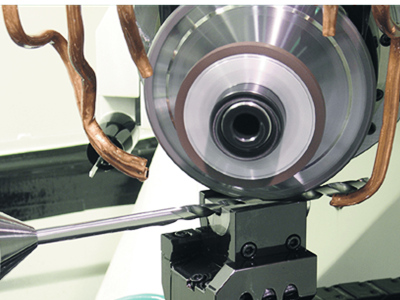

Grinding characteristics of stainless steel

Grinding burn

In the grinding area of the grinding wheel, there are countless sand particles grinding the workpiece at the same time. The temperature of the grinding point of the grinding grain is very high, generally exceeding 1000℃. The temperature of the grinding point is conducted to the surrounding area, thus forming the temperature of the grinding zone of the grinding wheel. Only a small part of the heat is lost through chips, grinding wheel, coolant and air. The workpiece surface temperature is high during grinding, which will produce thermal deterioration layer on the workpiece surface and cause grinding burn.

Stainless steel material plasticity and toughness, and can still maintain high strength under high temperature conditions, the small abrasive in the grinding wheel under the above conditions easy to produce blunt, resulting in the deterioration of the cutting conditions, friction intensification, will also make the cutting force in the grinding process increased.

Stainless steel has good plasticity, so good plasticity will bring resistance to the rotary grinding wheel. At the same time, because of the good plasticity of stainless steel, the contact area between it and the grinding wheel will be relatively increased, and the friction heat will increase. Grinding stainless steel plastic deformation force is large, will produce a lot of grinding heat, and stainless steel because of titanium element, resulting in its thermal conductivity is low, according to the record, about 1/3 of 45 steel, so that the grinding area grinding heat is not easy to disperse, resulting in grinding area temperature rise, can be as high as 1000℃. Under such a high grinding temperature, grinding burns, large residual tensile stress and cracks are easy to form on the grinding surface.

The grinding chips are easy to clog the pores of the grinding wheel

During the grinding process, a large number of chips are attached to the surface of the grinding wheel, which is called grinding wheel blockage. There are two types of clogging: one is invasive clogging, that is, chip drilling into the surface space of the grinding wheel, which is prone to occur when grinding steel. One is adhesive type plugging, where the chip is fused on the surface of abrasive and binder, and the abrasive cutting edge is covered. When grinding ductile materials with low melting point.

The work hardening trend is serious

Stainless steel plasticity, in the grinding process, in the grinding wheel rotation cutting constraints, the machining surface will produce plastic deformation, plastic deformation will make the lattice distortion, so stainless steel processing is easy to produce hardening layer. The work hardening tendency of grinding Austenitic stainless steel is stronger, and the hardness of the hardened layer is often 1.4-2.2 times higher than that of the matrix.

Selection of grinding processing dosage

1) Selection of grinding wheel speed

When grinding stainless steel, the grinding speed is not more than appropriate. If the speed of the grinding wheel is too high, the grinding chip will adhere to the grinding wheel, and the grinding wheel will lose its cutting ability. A small speed of the grinding wheel will reduce the risk of grinding burn.

2) Workpiece speed

The workpiece speed changes with the speed of the grinding wheel. It is not that simply increasing the speed difference between the grinding wheel and the workpiece will be more beneficial to the quality of the workpiece. There is a certain proportional relationship between them, because increasing the workpiece speed is equivalent to increasing the circular feed.

3) Grinding depth

Coarse grinding, generally take; Fine grinding, generally take about. When grinding stainless steel, if the grinding depth is too small, grinding burns and grinding scratches are easy to occur.

4) Feed rate

When grinding stainless steel externally, the feed of coarse grinding is desirable, where is the width of the grinding wheel; The feed of fine grinding is desirable. When the grinding depth is large, the smaller value is taken, and when the grinding depth is small, the larger value is taken.

---EDITOR: Doris Hu/ Cindy Chen

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]