CIOE 2022 (the 24th China International Optoelectronic Exposition), will be held from September 7-9, 2022 at Shenzhen World Exhibition and Convention Center.

Known as the world's largest optoelectronic event, CIOE 2022 will showcase up-to-date optoelectronic technologies and comprehensive solutions for optoelectronic applications, enabling industry players to source optoelectronic products, to gain latest marketing insights and to network with key Chinese optoelectronic players.

China international optoelectronic exposition (CIOE) is the world's most scale and the influence of the photovoltaic industry exhibition, comprehensive coverage of information communication, laser, infrared, ultraviolet, precision optics, chip materials, camera technology and application, intelligent sensor, the new show section, such as photoelectric display and application field of photoelectric innovation oriented technology and integrated solutions, Moresuperhard has participated CIOE many times and participated in the exhibition for the first time in September 2021. In 2022, Moresuperhard photoelectric team will go to Shenzhen to participate in the exhibition again, providing "cutting, grinding and polishing" solutions for the processing of high-precision single crystal cutting tools and photovoltaic semiconductor materials for you.

Exhibition Time: Sept.7th-9th, 2022 (Wednesday-Friday)

Venue: Shenzhen International Convention and Exhibition Center, China (Bao 'an New Hall)

Address: Zhancheng Road, Fuhai Street, Bao 'an District, Shenzhen City, Guangdong Province

Booth number: 11E07

In this exhibition, Moresuperhard will bring the following propducts to meet with you

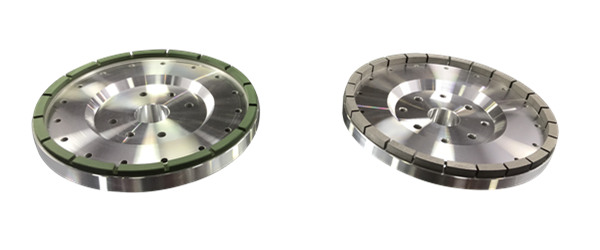

1. Vitrified diamond grinding wheel for CVD cutting tools:

Moresuperhard diamond wheel for precision grinding single crystal diamond, With Ultra-high precision. The PG seris is a CNC grinding machine for single or mono crystal diamond tool manufacture. The PG seris enables the automated production of ultra-high precision diamond tools.

Coborn PG series offers automated, ultra-high precision grinding, designed to meet the most complex of demands by toolmakers working with natural (MCD) or synthetic single crystal diamond (SCD), manufactured by either high pressure high temperature (HPHT) or chemical vapour deposition (CVD).

Coarse grinding: W40, W20

Semi-fine grinding: W10,W7, W5

Fine grinding: W3.5, W2.5, W1.5

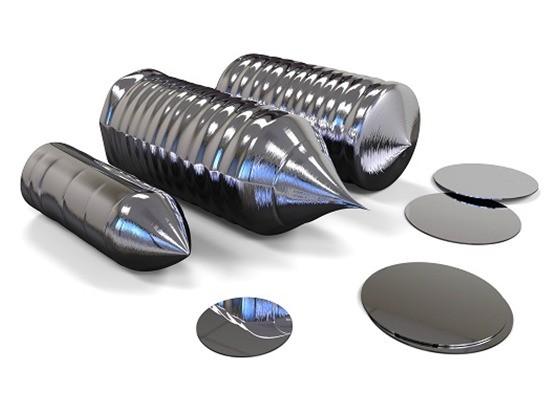

2. Diamond Wheels for Silicon Ingot, Cylindrical Grinding/ OD Grinding

Cylindrical diamond grinidng wheel for peripheral grinding of silicon ingots, or processing the outer surface of silicon ingots and to make orientation flat, for semiconductors and electronics parts, automobiles and photovoltaic industies.

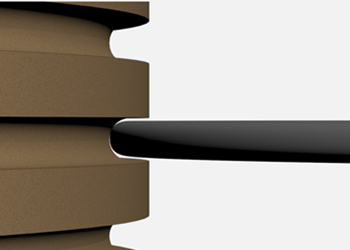

3. Diamond edge grinding wheel for wafer :

Edge grinding wheel, chamfering wheels for sapphire substrate, silicon carbide substrate and silicon wafer, liquid crystal panel, ITO glass, PDP glass, quartz glass, microcrystalline glass, photovoltaic glass, automotive glass. A small diamterer wheel for notch grinding.

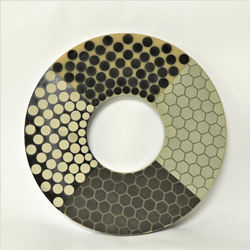

4. Vitrified diamond double disc grinding wheel

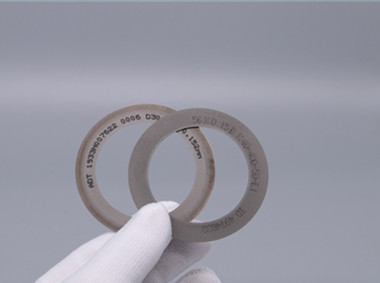

5.Back Grinding Wheel for LED Substrate

6A2H/6A2T back Grinding Wheel for LED Substrate LED industry for back grinding of sapphire wafers, silicon wafers, gallium arsenide, and gallium nitride wafers.

6.Back grinding wheel for Silicon Ingot

Vitrified diamond back grinding wheel back thinning, front grinding and fine grinding of discrete devices, integrated circuit substrate silicon wafers, sapphire epitaxial wafers, silicon wafers, arsenide, GaN wafers, silicon-based chips, etc.

The back grinding wheels can be used for the Japanese ,German, American, Korean and other grinders ( Such as NTS, SHUWA, ENGIS, Okamoto , Disco, TSK and STRASBAUGH grinding machine, etc ).

Moresuperhard back grinding wheel has good retention, high grinding efficiency and less dressing times.

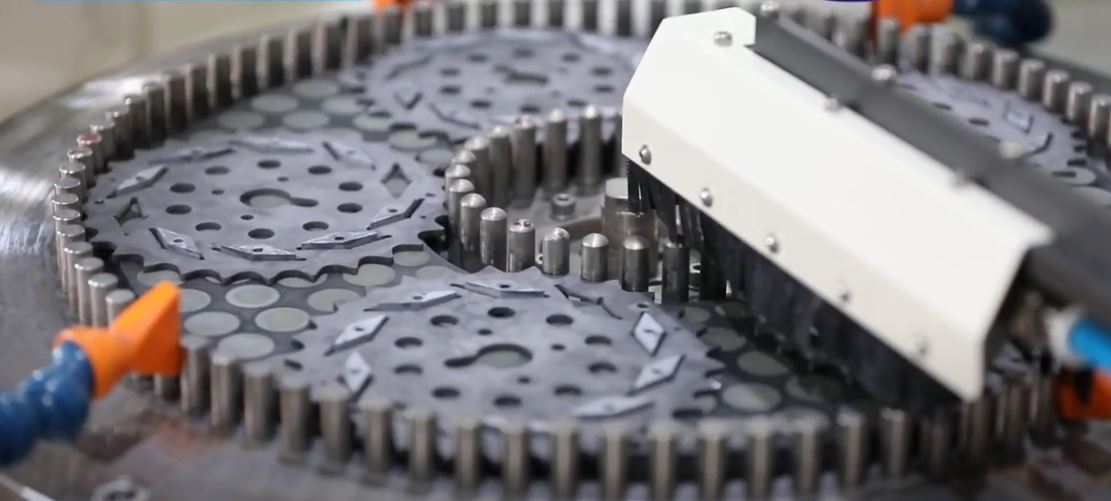

7.Diamond dicing blade

Moresuperhard produce huless diamopnd dicing blade(resin diamond dicing blade, metal diamond dicing blade) and electroform hub type diamond dicing blade.

Resin bonded blades have excellent cutting ability that help reduce chippingm fractures, can efficiency improve cut quality and efficiency on ductile and gummy materials such as QFNs and coppers and on hard and brittle materials such as glass and ceramic.

8. Polishing pad and diamond compound

Polyurethane (PU) Polishing Pad for polishing and finishing of glass, LCD/LED substrates, precision optics, hard disk, metal and semiconductor wafer surfaces.

Diamond compound for polishing tungsten steel molds, optical molds, injection molds, etc.

Moresuperhard is committed to technology development and innovation, with "create with grinding grinding more than the value of" the idea, provides the high quality for the customer and market continues the superhard products, for your high efficiency grinding high precision single crystal cutting tools provide solution, for the machining of the semiconductor industry to provide "cut the polishing" series solution.

Looking forward to meet you on CIOE!

---EDITOR:Doris Hu

---POST:Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]