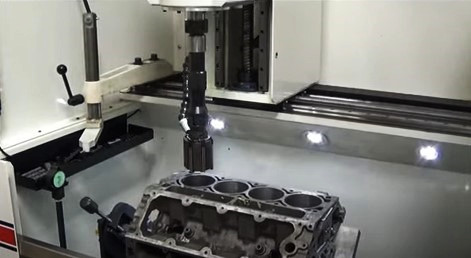

Honing is a method of finishing workpiece surface at low cutting speed. It is a special form of grinding and an efficient machining method in finishing. This process can not only remove large machining allowance, but also improve dimensional accuracy. Geometric precision and effective machining methods to reduce surface roughness are widely used in automobile parts manufacturing。

High machining accuracy

Honing can improve the shape accuracy of the workpiece, especially for some small and medium-sized through holes, the cylindricity of which can be up to 0.001mm. For some parts with uneven wall thickness, such as connecting rod, the roundness of which can be up to 0.002mm. If there is no ring groove or radial hole, the straightness of honing is less than 0.01mm/1m, and the precision of honing is higher than that of grinding. During grinding, the bearing supporting the grinding wheel is located outside the grinding hole, which will cause deviation, especially for small hole machining.

Good surface quality

The surface is cross mesh, which is conducive to the storage of lubricating oil and the maintenance of oil film has a high surface support rate (the ratio of the actual contact area between the hole and the shaft and the matching area between the two), so it can bear large load and wear resistance, thus improving the service life of the product. Due to the low honing speed and the surface contact between the honing stone and the hole, The average grinding pressure of each abrasive particle is small, so the heat of the workpiece is small, the temperature of the cutting area can be maintained at 50-150, the surface of the workpiece almost no thermal damage and metamorphism layer, small deformation.

Wide processing range

Main processing of a variety of cylindrical holes: through holes, axial and radial discontinuous holes, such as radial holes or slots, keyway holes, spline holes, blind holes, In addition, the special honing head can also be used to process conical holes, oval holes, etc., but because of the complex structure of the honing head, the cylindrical body can be honed without the outer round honing tool, but the margin removed is far less than that of the inner round honing

Small cutting allowance

Honing is the one that removes the least amount of margin among all machining methods. In honing, the honing tool takes the workpiece as the guide to remove the excess amount of the workpiece and achieve the required precision of the workpiece

Strong ability to correct holes

Shortcomings due to other processing technology, the machining process will appear the following defects: such as round, bell, corrugated hole, small size, drum-shaped, taper, boring cutter, hole deviation and surface roughness, the honing process can remove the minimum machining allowance and greatly improve the hole and the size precision of cylindrical, roundness, Straightness, cylindricity and surface roughness.

Diamond/CBN honing reamer

More Superhard provides precision bore honing finishing solution, the honing tools include

- Diamond honing stone, cbn honing stick

- Single pass diamond honing tools

- Cylinder honing tools

- Diamond honing head

- Diamond cylinder hone

Honing Machine: Sunnen, Nagel, Gehring, Nissin, Engis, Fuji, Mas and other honing machines.

Diamond honing reamer have fixed and adjustable diamond honing honing reamer reamer, and contains ladder diamond honing reamer, from literal meaning can also see, fixed electroplating diamond reamer is a fixed size, guide, before the blade, the guidance as a whole, while the adjustable electroplating diamond reamer is adjustable reamer size, after the reamer body wear, can be in bushing vertebral body The upper trace movement can compensate the wear size, so that the cutter body can be reused, thus extending the service life. The fixed electroplated diamond reamer is more used in the blind hole, and the adjustable diamond honing reamer is more used in the through hole.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]