Based on the characteristics of high heat resistance and inertia of CBN material, CBN wheel in bearing processing, its thermal stability and thermal conductivity is good, can work normally in the high temperature of 1300~1560℃, suitable for high strength alloy steel and high speed steel grinding process with high thermal sensitivity, and can keep the material smooth, will not leave grinding cracks.

Vitrified CBN grinding wheel is based on CBN grinding wheel technology through technical improvement, its stability, heat resistance and acid and alkali resistance is strong, in the process of working, its coefficient of thermal expansion is small, not easy to clog, so it can keep the surface of the material smooth.

Grinding steps:

1. Forging bearing outer ring blank.

2. Rolling preforming

3. Outside diameter, end face, inside diameter and raceway;

4. After carbonitriding quenching and tempering, quenching temperature 850 ~ 870°C, quenching 250 ~ 300°C tempering.

5. With a profile grinding machine grinding bearing outer ring a end face

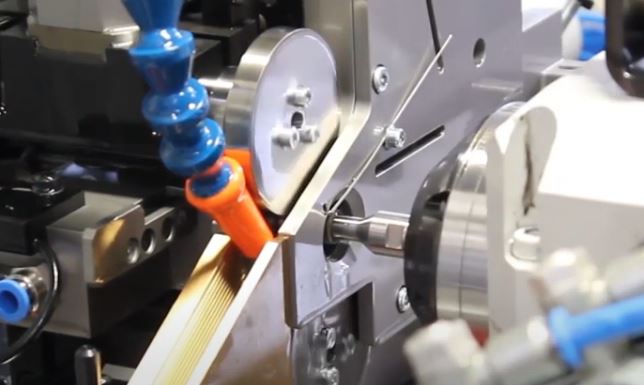

6. Bearing outer ring outer circle and raceway grinding.

7. The other end of the bearing outer ring rough grinding

8. Bearing outer ring outer circle and raceway polishing fine grinding nine, the other end of the bearing outer ring polishing fine grinding.

When roughing outer raceway roughing outer raceway, the grinding amount left for fine grinding should be appropriate, and the precision of ellipse, edge roundness, raceway position, raceway side swing and groove shape of roughing raceway should be ensured to meet the technological requirements, which can not be ignored. If the precision of coarse grinding raceway is poor, in order to make the precision of fine grinding raceway meet the technological requirements, it is bound to increase the rough grinding allowance artificially. Large retention, fine grinding feed, cutting amount will increase, in the long run, will affect the precision of the machine tool, resulting in fine grinding precision decline. The test results show that the allowance for fine grinding is about 0.10-0.15mm when the precision of oval, edge roundness, raceway position, raceway side swing and groove shape of rough-grinding outer raceway of medium deep groove ball bearing meets the technological requirements. In addition, burns are not allowed when roughing outer raceway.

---EDITOR: Doris Hu

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]