Brake disc, also called brake disc, is one of the key parts of automobile braking system, its precision and quality is the premise of ensuring the safety of automobile driving. Therefore, when processing the brake disc, choose the right tool, improve the processing quality and processing efficiency, is a very important problem.

Brake is a mechanical brake, also known as a reducer, that slows the car down. In simple terms: the car brake pedal under the steering wheel, step on the brake pedal, then the brake lever linkage pressure and transferred to the brake pad on the brake drum stuck the brake wheel, so that the car decelerate or stop running. A car's manual brake is on the side of the shift, connected to the brake bar.

There are common bicycle brakes, which are fixed on the frame of the rod brake or disc mounted brake brake to slow down.

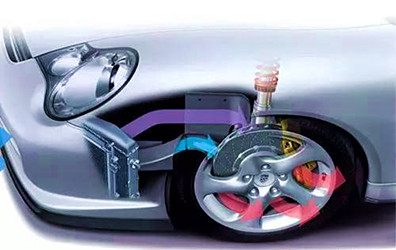

The brake system hidden in the wheel is an important device that plays the role of stopping the car in motion. The brake device generates friction between the brake pad and the wheel drum or disc, and converts the kinetic energy of the car into heat energy consumption in the process of friction. The common brake device has "drum brake" and "disc brake" two types.

Brake disc material:

Most of the car brake discs are made of cast iron, the material used in China is gray cast iron 250 standard, that is, HT250, consistent with the G3000 standard of the United States.

HT250 not only has high strength, good wear resistance and heat resistance, but also has excellent shock absorption performance. Therefore, most brake disc manufacturers choose HT250 material for casting processing.

Brake disc processing process:

After the brake disc blank is cast, it enters the machining process. Generally speaking, the brake disc processing process is mainly divided into seven steps:

(1) Rough turning outer circle and end face

(2) Semi-finishing turning outer circle and end face

(3) Fine turning outer circle and end face

(4) Milling end groove

(5) drilling

(6) Deburring

(7) Inspection warehousing

Brake disc tool selection:

At first, brake disc manufacturers use carbide tool to process brake disc, but with the development of material technology and the improvement of processing efficiency requirements, carbide tool due to low hardness, no wear resistance, cutting speed is not high problems, has been unable to meet the needs of large quantities of processing brake disc.

At present, CBN tool is mostly used. Because the cubic boron nitride tool has high hardness and good wear resistance, it can meet the requirements of high speed cutting brake disc, improve the processing efficiency of brake disc, thus reducing the processing cost of brake disc.

Special requirements for brake disc casting :

The casting mechanism of brake disc is relatively simple, but because it is the key part of automobile braking system, there are some special requirements for casting.

(1) The brake disc rotates with the wheels when the car is running, so the dynamic balance is highly required to prevent the car from shaking, so the control of the wall thickness difference is very strict.

(2) when the car is braking, the brake shoe (or brake caliper) and its friction, so the brake disc working face wear resistance (hardness) is good.

(3) at the same time of friction, a lot of heat will be generated, so the brake disc casting is required to have a certain thermal fatigue resistance.

Brake disc processing difficulties analysis:

(1) The initial casting material of brake disc is generally HT200, but with the increase of automobile speed and power, there are higher requirements for casting material: the material is required to reach or exceed THE HT250 standard, and the hardness of body is above 180HBS. Therefore, there are higher requirements for the hardness of machining tools.

(2) Brake disc is a typical thin-wall disc parts, the processing content is mainly turning and drilling processes, how to ensure the size and shape accuracy of the finished product, for the traditional tool is a challenge.

(3) The brake disc two end surface processing quality requirements are very strict, the surface roughness should be below Ra1.6, the use of traditional hard alloy tool, not only processing surface roughness is not easy to achieve Ra1.6, and the tool durability is low, productivity is not.

Processing brake disc selection of CBN tool

Brake disc processing tool innovation

(1) CBN positioning pit inserts and integral drilling inserts

Convenient tool positioning, especially suitable for profile machining and high speed cutting.

(2) CBN polishing blade

The same feed, get higher surface quality.

The same surface roughness, can use large feed, reduce the processing time of single piece, improve the processing efficiency.

Note: not suitable for copying processing. Suitable for high rigidity machine tools and processing parts .

(3) CBN positioning pit inserts and integral drilling inserts

Convenient tool positioning, especially suitable for profile machining and high speed cutting.

(4) CBN polishing blade

The same feed, get higher surface quality.

The same surface roughness, can use large feed, reduce the processing time of single piece, improve the processing efficiency;

(5) CBN coated blade

Smooth coating and CBN perfect combination, can obtain more excellent cutting performance, improve machining accuracy and life.

---EDITOR: Doris Hu

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]