Tool steel refers to a variety of carbon steel and alloy steel that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures.

Grain sizes for grinding tool steel are generally in the range 24-100 mesh.

Coarse grain izes are used for rapid rate of remo val, when grinding large workpieces, grinding softer materials or when the contact surface of the grinding whee is large. Fine grain sizes are used to oroduce high surface finish, when grinding hard materials or when the contact surface of the grinding whee is small. The surface smoothness of the ground part depends not only on the grain size of the grinding wheel. The sharpness of the wheel, the bonding material used and the hardness of th wheel also play a considerable part ir determining the surface finish produced.

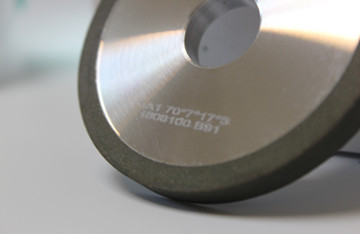

CBN grinding wheel is made of CBN/ cubic boron nitride powder and resin, ceramic, metal and other binder through high pressure and high temperature sintering. The high speed steel grinding tool CBN wheel has the advantages of high hardness, high grinding efficiency, good wear resistance and high temperature stability, etc. The high speed and high tool grinding can obtain high quality workpiece surface quality, without the defects such as workpiece burn and grinding crack, which can reduce the overall processing cost.

In order to enhance the wear resistance of a tool steel, the steel is alloyed with carbide-forming alloying elements, of which the most important are chromium and vanadium. The steel must also have a high carbon content if carbides are to be formed. The diagram, Figure 5, shows the hardness of the basic phases found in a tool steel, the hardness of the most common carbides found in tool steel and the hardness of commonly used grinding abrasives. As can be seen in the figure, it is only diamond and CBN that are arder than all the carbides that are ound in a tool steel. However, as mentioned earlier, diamond is unsuitable for grinding steel. The quantity and the size of carbides in a steel has a very considerable effect on the ease of grinding of the material.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]