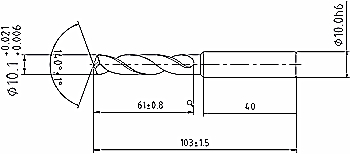

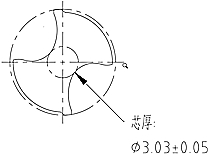

1. Test tool specifications: integral HM twist drill D10.1*61*103*SD10.

2: Test grinding wheel specifications: strength slotted grinding wheel 1A1-125-10-10-D64

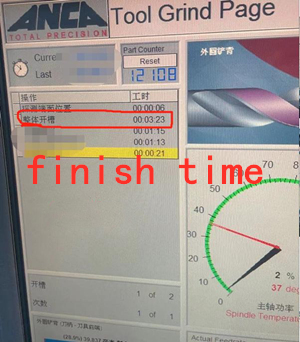

3: Test machine: ANCA TX7+

4. Test data:

Grinding wheel speed: 2800RPM(18M/S)

First cut | Second cut | |

Grinding depth | 3.5mm | 0.03mm |

Feed | 80mm/min | 200mm/min |

First groove processing time | 1min12s | 30 sec |

Second groove processing time | 1min12 s | 30 s |

Grooving Processing time | 3min 24 s | |

Number of processing | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

Load | 8% | 9% | 12% | 10% | 15% | 20% | 25% |

Number of | 8 | 9 | 10 | 11 | 12 | ||

Load | Oil stone

| 7% | 9% | 13% | 18% | 23% | Oil stone

|

Processing time | 3min 24s Change is very small | ||||||

A total of 100 units were tested. The first 7 units were tested to the limit. The maximum load of the machine was set at 25%.Comprehensive analysis:

After the sharpening, the load of the machine tool can be reduced, the grinding force of the grinding wheel can be maintained, and the outer diameter of the grinding wheel does not change much. In conclusion, the hardness of the grinding wheel is hard, the grinding wheel is easy to block holes, and the grinding wheel maintainability is good.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]