High-efficiency machining plan for aerospace titanium alloy structural parts

Aviation structural parts have a wide variety and complex structure; in addition, because aviation structural parts are mostly thin-walled parts, the material removal rate is large, and the processing cycle is long, so the rapid delivery of aviation structural parts can bring greater economic benefits to aviation enterprises.

In order to reduce the weight and cost of the airframe, the aerospace industry usually uses composite materials and titanium alloys to manufacture the main parts of the airframe. Among them, titanium alloy is a difficult-to-process material with complex processing characteristics, which brings a series of challenges to manufacturers.

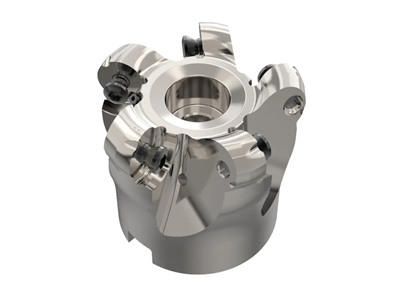

R8 round blade milling cutter

The blade is equipped with positioning grooves and matched with the unique positioning screw of the cutter body to ensure smooth cutting, the blade is not easy to slip, impact resistance, small cutting force, and adapt to the needs of different technological occasions. The blade is coated with MS2050, which is Seco's preferred material for milling titanium alloys under most working conditions. The coating is composed of F40M coating and silver NbN (niobium nitride) new surface layer, which can effectively avoid chemical reactions with the workpiece material, thereby prolonging the life of the blade and processing efficiency.

JS720 & 730 end mill

1) 6-edge-9-edge dense-tooth tool, high cutting efficiency and stable performance. When processing difficult-to-process materials such as titanium alloys, combined with 3D processing CAM software, higher linear speeds can be used when cutting width of 7-12%*Dc. Suitable for mass production of difficult-to-process materials such as titanium alloys.

2) It is widely used and easy to use. It can be adapted to the side milling processing with a cutting width of 40%*Dc, and it has superior performance in the power milling processing strategy. Suitable for various applications such as rough machining, semi-finishing and finishing.

3) Comprehensive size. The diameter range is from d6-d25, the blade length is 2.5-3*Dc, the tip fillet is from R0.5-R6 and the ball nose tool. Contains rounded corners of commonly used aerospace parts. Some tools also provide the structural design of the chip groove. It is convenient for users to choose.

New JS750 end mill

When machining, use from the inside to the outside. When processing thin webs, try to use vacuum adsorption processing. On the premise of sufficient tool rigidity, the risk of vibration of products processed by small-diameter tools is smaller, and the smaller the rounded corners of processing tools will cause vibration. The smaller the risk, the more margin is left before finishing to ensure the rigidity of the web. For thin webs or ultra-thin webs with a large area, the finishing is processed in two axial layers in place, and the layer-first processing strategy is adopted.

JS754 and JS755 tools are very suitable for processing thin webs, with excellent performance and good cost-effectiveness, especially for stainless steel and high-temperature alloy processing. This series of tools are versatile and can be used for traditional side milling, roughing, slot milling, advanced roughing and dynamic milling. The bottom edge of the tool adopts an optimized design, which is conducive to Z-direction cutting, and the unequal pitch design can reduce the risk of tool vibration. Using HXT coating, polishing treatment and cutting edge treatment, higher linear speed can be used, and chip evacuation is smoother at the same time.

JS522 Long Edge Finish Milling Cutter

JS522 is a finishing tool with a long chip flute. It not only meets the strict requirements of the aerospace market for verticality and fine surface roughness, but also improves the material removal rate, so it is especially suitable for processing titanium alloys and aluminum alloys. Into aerospace structural parts.

· Good surface quality

· Wall verticality reaches 0.015 mm

· No steps

· No need for polishing

The tool allows the tool to be compensated by the pre-inverted taper design of the tool

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]