1. High grinding efficiency

When grinding cemented carbide, its grinding efficiency is several times that of silicon carbide. When grinding W12 Cr4V4Mo high-speed steel with poor grinding performance, the average efficiency is increased by more than 5 times.

2. Has high wear resistance

The wear resistance of diamond grinding wheels is very high, and the consumption of abrasive particles is very small, especially when grinding hard and brittle workpieces. When using a diamond grinding wheel to grind hardened steel, its wear resistance is 100 to 200 times that of general abrasives; when grinding hard alloys, it is 5000 to 10,000 times that of general abrasives.

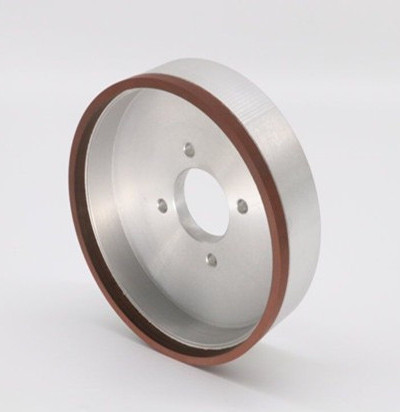

3.Small grinding force and low grinding temperature

The hardness and wear resistance of diamond abrasive grains are high, and the abrasive grains can keep sharp for a long time, and it is easy to cut into the workpiece. When grinding cemented carbide with a resin-bonded diamond grinding wheel, the grinding force is only 1/4 to 1/5 of the grinding force of ordinary grinding wheels. The thermal conductivity of diamond is very high, which is 17.5 times that of silicon carbide, and the cutting heat is quickly transferred out, so the grinding temperature is low.

4. The ground workpiece has high precision and good surface quality

Grinding cemented carbide tools with diamond grinding wheels, the roughness of the surface and cutting edge is much lower than grinding with boron carbide grinding wheels, the cutting edge arc radius is small, the cutting edge is very sharp, and the tool durability can be increased by 1 to 3 times. The roughness of workpieces processed with diamond grinding wheels can generally reach 0.1~0.025μm, which can improve the finish by 1~2 level compared with ordinary grinding wheels.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]