High grinding force

Diamond is the hardest substance among known minerals, and the amount of wear when matched with various metal and non-metal materials is only 1/50~1/800 of that of cemented carbide. The hardness (HV) of PCD is 80~120KN/mm², second only to single crystal diamond, and much higher than carbide. When PCD is grinding with diamond wheel, the initial cutting strength is very high, which is more than 10 times of the carbide (0.4MPa). The specific grinding can reach 1.2×104~1.4×105J/mm³; therefore, the grinding force is much higher than that of cemented carbide.

Small grinding ratio

Due to the high hardness and wear resistance of PCD (relative wear resistance is 16 ~ 199 times of carbide), the grinding ratio of PCD is only 0.005 ~ 0.033, which is about 1/1000 ~ 1/100000 of carbide. The grinding efficiency is only 0.4~4.8mm3/min. Therefore, in order to ensure the quality and removal of cutting tools, the grinding time is very long and the processing efficiency is very low. In addition, when the hardness, content, and particle size of PCD are different, the grinding time is also very different.

Particle size matters a lot

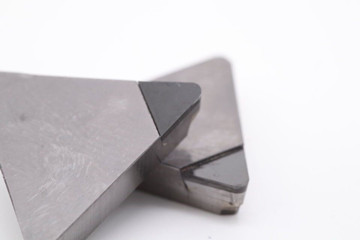

PCD materials used for cutting tools can be divided into three categories according to particle size: coarse particle size (20 ~ 50 μm), medium particle size (about 10 μm) and fine particle size (~ 5 μm). The grinding force and grinding ratio of PCD materials differ by several to tens of times. Rough-grain PCD has the highest grinding ratio and the most difficult grinding. After grinding, the cutting edge has the most serious jagged shape and the worst quality, but the wear resistance is the strongest; The fine-grain PCD has the lowest grinding ratio, easier grinding, and the best edge quality after grinding.

Semiconductor Industry Solutions

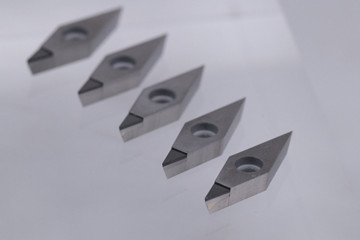

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]