Traditional woodworking saw blades are made of cemented carbide, and now PCD saw blades are entering the market with a brand new attitude. We all know that cemented carbide saw blades should be sharpened with resin diamond grinding wheels, so do you know what kind of grinding wheels should be used for grinding PCD saw blades? What are the advantages of this kind of grinding wheel?

Because the PCD is made from the synthetic diamond, it’s very hard, usually, we must use very high concentration diamond wheels like vitrified bond diamond wheels, which content 2times synthetic diamond than resin diamond wheels in each cubic mm³. As we know, resin bond are always good at the carbide tools, but not PCD tools. Even that, when we use vitrified bond diamond wheel to grind PCD with 1000-6000# grit size even much more finer one, often we will remove almost as much stock from the wheel as comes off the PCD tools.

MORESUPERHAD can supply quality PCD grinding wheel at very long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, we make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won’t lose the efficiency while we still want enough life from the wheels. So it will help you get fast, stable, much more PCD tools in unit time.

What are the advantages of this kind of grinding wheel?

1.The porous structure of the abrasive improved diamond exposure and can prevent vertical streaks on workpiece and improve surface quality.

2.Accurately control geometric tolerances to make a good abrasive layer.

3.Good self-sharpening, high grinding efficiency, high wear resistance and less abrasive grain consumption.

4.High precision workpiece. PCD tools can reach high efficiency, good surface finish and edge no chipping.

5.Vitrified bond wheels offer tool life greater than 150 times that of a resin bond wheel and can be easily trued and dressed on the machine.

Semiconductor Industry Solutions

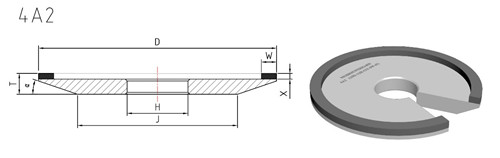

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]