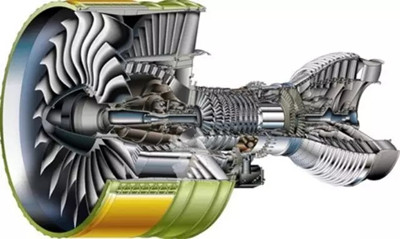

The aerospace turbofan engine has extremely high technology content and is known as the "industrial crown". In recent years, the aerospace industry has developed rapidly, and the performance of materials has become higher and higher, which has made the application of difficult-to-process materials such as titanium alloys and high-temperature alloys more and more It is widely used in shafts, turbine disks, combustor casings, combustion nozzles, etc., and has become an irreplaceable key material for the hot end components of gas turbine engines.

These are typical hard-to-machine core components, with the following typical characteristics:

1. Complex structure, such as deep hole cavity, cavity weld scar after welding, etc., overhanging, difficult chip removal during processing, easy to cause vibration, and sufficient programming is required Taking into account the problem of cutting in and out of the tool during rough and finishing machining, as well as the control of tool access, it is also necessary to fully consider the safety gap between the tool and the workpiece

2. Thin-walled structure, the cutting of the tool should be fully considered when selecting the tool and processing The influence of force magnitude and direction on the degree of deformation of the workpiece

3. Work hardening tends to be large, for example, the hardness of the unstrengthened GH4169 substrate is about HRC37, and the surface after cutting produces a hardened layer of about 0.03 mm. The hardness increases to about HRC47, and the degree of hardening is as high as 27%. Work hardening has a great influence on tool life and usually produces severe boundary wear.

The complexity of the structure of the core components of aero-engines, the strict processing requirements and the difficult processing of materials require tool companies to have higher products and services. We provide many safe and efficient processing solutions for the industry.

Aiming at the mature processing scheme of the inner and outer grooves of the typical combustion chamber casing, we use Top-Notch inserts as the substrate. The Top-Notch type inserts have the characteristics of strong clamping rigidity, light cutting force, and excellent chip breaking performance. , Especially suitable for processing thin-walled parts.

Part material: | nickel-based alloy |

Machine tool type: | vertical CNC lathe |

Use blade: | NRD3062L |

Diameter of processed parts: | 780mm |

Processing speed: | 50m/min |

Speed: | 20 rpm Feed |

rate: | 0.1mm/rev |

Cutting depth: | 0.8mm |

Coolant type: | external cooling |

Service life of each cutting edge: | 12.5 min |

30% increase in processing efficiency | |

The total time required for each processing part 12.5min | |

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]