Gear transmission, as an efficient power transmission method, is widely used in various industries. With the updating of processing technology, soft tooth surface gears have been gradually eliminated and replaced by carburizing and hardening hard tooth surface gears. It achieves greater torque transmission in a smaller volume, and in the bending strength and contact strength of the teeth.

What are Hardened Gears?

Hard-toothed gears refer to gears with a hardness above HRC40. Usually, heat treatment is required for quenching or carburizing and quenching. After heat treatment, the workpiece will be deformed due to heat treatment, and the precision of its pre-heating processing will generally be reduced by 1-2 grades. Therefore, finishing is required after heating. The most common processing method for such high-precision hardened gears is to hob first, then carburize and quench, and finally grind the tooth surface. This process can make the entire tooth surface obtain the same structure and carburized layer. Depth, the final hardness of the tooth surface can reach HRC58-HRC62, and high geometric accuracy and surface finish of the tooth surface can be obtained.

Smaller modulus workpieces are processed with integral hobs, and the material is generally coated high-speed steel or powder metallurgy. Due to the large size of the hob body and the high cost of the gear with a large modulus, it is generally designed as an insert hob. Such hobs need to regularly check the wear of each blade, and replace the worn or chipped blades. Drop: for extra large modulus gears (generally M>22), gear milling cutters are generally used for processing.

Gear grinding is the most effective and reliable method to obtain high precision of the tooth surface, in order to grind off the hobbing allowance and its deformation. In order to make the force and meshing of the gear more reasonable under load, the gear will be corrected to a certain extent on the standard involute tooth shape and tooth direction. The CNC gear grinding machine grinds the tooth shape to the required geometric accuracy through preset parameters. And by selecting the matching grinding wheel and dressing parameters, the grinding can achieve the final roughness requirement. The general requirement in the industry is Ra0.8, and there are also some special applications, such as wind power gearboxes, which need to reach Ra0.6 or even higher. Its processing method is divided into developing grinding and forming grinding.

Generated grinding method

The generating method processing is similar to the hobbing principle. During the grinding process, since the grinding wheel is continuously meshed with the tooth to be ground, the involute shape of the tooth is developed, and there is no interruption in the grinding process, so its processing efficiency is very high. In actual processing, due to the size of the grinding wheel, generating grinding is suitable for processing smaller modulus gears (generally M<=12).

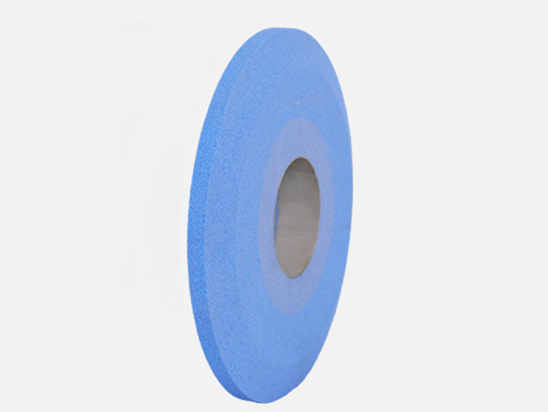

During the grinding process, the grinding wheel made of alumina can be used, and it needs to be processed according to the set wear life length and the method of serial hob shifting. In the process of hob shifting, the grinding wheel is continuously updated to achieve the highest material removal efficiency; in the process of fine grinding, the hob is shifted step by step, and the grinding wheel is ground at the same position to achieve the stability of the tooth surface quality. For the mass production of a single variety of gears, high-precision CBN worm grinding wheels can also be used, which can greatly improve the grinding efficiency, but the cost is relatively high.

Generating grinding has high requirements on the precision and stability of machine tools. At present, well-known machine tool companies include Reishauer in Switzerland and Liebherr in Germany. The precision of machining gears can reach 4-5 grades or even higher.

Moresuperhard can provide worm grinding wheel for gear, can matach grinding machine: KAPP, Haas,MonnierZahner, SAMP,Gleason,Felsomat,etc.

Form grinding method

The grinding wheel is trimmed to the same shape as the tooth shape by the diamond wheel, and the teeth are ground one by one. This production method is relatively flexible. When changing the gear model, only the grinding wheel needs to be trimmed to the corresponding shape. The entire dressing and machining process is controlled by preset CNC axes. The leading companies in this processing technology in the world are Gleason, Hoefler, etc. The processing accuracy of the profile grinding machine produced by them can reach level 3, and because the shape of the entire tooth surface is continuously ground by the profile grinding wheel at one time, so The roughness of the entire tooth surface can reach Ra0.4-Ra0.8.

--EDITOR: Doris Hu

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]