Characteristic of copper?

Diamond is a crystal of a single carbon atom, and its crystal structure belongs to the equiaxed face-centered cubic system with the highest atomic density. The connection bond between carbon atoms in diamond crystal is sp3 hybrid covalent bond, which has strong binding force, stability and directionality. The unique crystal structure of diamond makes it have the highest hardness, rigidity, refractive index and thermal conductivity in nature, as well as extremely high wear resistance, corrosion resistance and chemical stability.

Advantages of CVD/MCD cutting tools?

The excellent properties of single crystal diamond can meet most of the requirements for precision and ultra-precision cutting tool materials, and it is an ideal precision cutting tool material. The uniform crystal structure of diamond without internal grain boundaries makes the cutting edge of the tool theoretically reach atomic-level straightness and sharpness. It has strong thinning ability, high precision and low cutting force during cutting; its high hardness and good wear resistance Resistance, corrosion resistance and chemical stability can ensure that the tool has a long life, so that it can carry out continuous cutting for a long time, and can reduce the impact of tool wear on the precision of the part; its high thermal conductivity can reduce the cutting temperature and the temperature of the part Thermal deformation.

Single crystal diamond tools, also known as single crystal tools, single crystal diamond tools, single crystal diamond blades, etc., are the main cutting tools in the field of ultra-precision machining. With extremely high workpiece precision and extremely low surface roughness, the cutting effect is very bright (mirror surface processing can be realized), and it is recognized as an ideal ultra-precision machining tool. According to different sources of materials, single crystal diamond tools are divided into MCD and ND. MCD is a synthetic diamond single crystal, and ND is a natural diamond single crystal. Due to the small amount and high price of natural single crystal diamond, it is mainly used for High-precision optical fields, etc.

Natural single crystal diamond tools are suitable for finishing copper, aluminum and their alloy materials, and are widely used in fields such as jewelry, watches, instruments and meters, LED products, acrylic products, aluminum products, aerospace, automobiles, etc., such as: motorcycle wheels, Turning cameras, high-gloss parts of mobile phone parts, precious metals, various hardware high-gloss casings, watch hubs, surface calendar windows, pens, fishing gear, contact lenses, etc. It has the characteristics of low loss, long life, easy to use, etc. and can guarantee extremely high processing accuracy and mirror finish.

How to turning or milling cutting tools

Case of MCD arc milling tools for milling copper:

MCD arc milling tools is widely used in non-ferrous metal 6C industry parts (high-gloss aluminum mobile phone case, high-gloss aluminum smart watch, communication accessories, automotive aluminum-copper parts, high-gloss aluminum products, gold and silver jewelry, optical components).

Both CVD and MCD arc milling cutter Moresuperhard can be produced, but the production cost of CVD is high. If only the mirror surface needs to be processed, MCD can fully meet the needs of customers and is the best choice.

The performance advantages of single crystal cutting tools:

1. The cutting edge of the single crystal diamond tool can be ground very sharply. It is not suitable for sticking the knife and producing built-up edge during cutting, and it can be used for ultra-thin cutting and ultra-precision machining.

2. The friction coefficient is low, the deformation is small during processing, and the cutting force can be reduced.

3. Single crystal diamond tool has extremely high hardness (10000HV), so as to obtain good wear resistance.

4. Selected single-crystal diamond cutter particles are used, which have good consistency and a service life that is 100 times, or even hundreds of times, that of cemented carbide cutters.

5. The cutting edge is observed under the 800 times Nomarski (Nikon) microscope without defects. When processing non-ferrous metals, the surface roughness can reach Rz0.1~0.05um, and the shape accuracy of the processed workpiece is controlled below 50nm.

6. Single crystal diamond tools can also effectively process non-ferrous metal materials and non-metal materials, such as copper, aluminum and other non-ferrous metals and their alloys, ceramics, unsintered hard alloys, various fiber and particle reinforced composite materials, plastics, Rubber, graphite, glass, etc.

How to choose grinding wheel for grinding copper?

Copper has good ductility, which is easy to cause porosity blockage, so that the grinding wheel loses heat dissipation ability.Then cause the workpiece burn or expansion deformation, belongs to one of the difficult grinding materials.

Copper

When grinding, the grinding wheel can be selected according to the characteristics of copper. The main processing properties of copper are as follows:

Grinding properties of copper

1.The grinding wheel is easy to be blocked and the workpiece is heated and deformed

Due to the good ductility of copper, it is easy to cause the blowhole blocking and the grinding wheel loses the heat dissipation ability, thus causing the workpiece to burn or expand and deform.

2.Copper material is easy to adhere, grinding slip, vibration

After grinding, the copper material is easy to adhere to the abrasive grain, so that the abrasive grain loses the grinding force, easy to leave vibration traces on the workpiece.

3.Easy to scratch, improve gloss is not easy

The grinding copper material is easy to stick to the surface of the grinding wheel and cause scratches as the grinding wheel rotates. It is not easy to improve the gloss.

Moresuperhard can improve the pore of its structure, via the treatment of pores can reduce the blockage, grinding heat and improve the adhesion problem.

Through the treatment of pore, can provide the chip hiding space, reduce the scratch problem. And fine grain still has large pores, even fine grain grinding wheel can still make large pores specifications, can simultaneously improve the gloss and avoid blockage, burn deformation!

The grinding wheel with the “pore technology” of both large and small pores can also dissipate heat smoothly with fine grain size, improve the surface roughness and at the same time, do not have to worry about grinding heat problem.

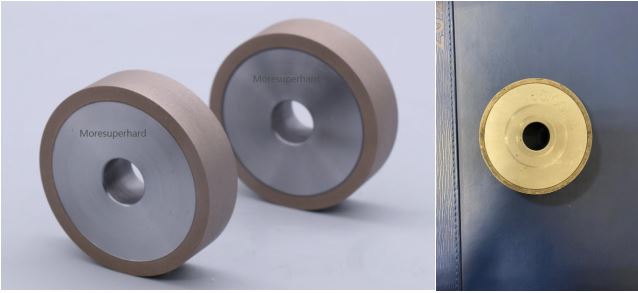

Moresuperhard developed a kind of metal bond diamond wheel to grind brass copper, if you are in need, feel free to contact us.

Case of resin diamond grinding wheel for grinding copper

Titanium Copper Alloy, Copper Alloy Grinding

Generally, when grinding copper, the pores of the grinding wheel are relatively large. In addition to the above-mentioned superhard grinding wheels, corundum, silicon carbide resin bonded grinding wheels or corundum vitrified bonded large porous grinding wheels can also be used.

Workpiece | T2 Copper |

Grinding method | Surface grinding |

Grinding wheel | resin diamond grinding wheel (diamond + CBN) |

Grinding wheel specification | 14A1 D300*35T*75H*25U*5X 220# |

Customer Problem | Sticking knife, requires frequent retouching |

Feedback from customers | The problem of sticking knives has been improved a lot, and the overall effect is good |

---EDITOR: Doris Hu

---POST: Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]