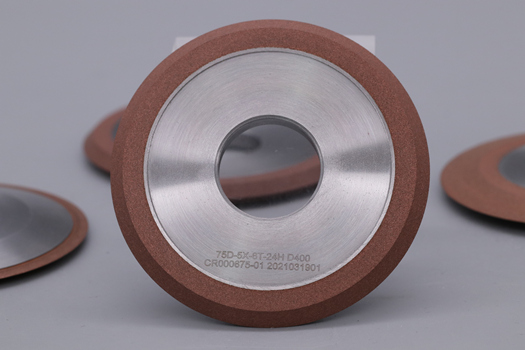

There is a unified international standard for the marking of grinding wheels. Its main elements include: shape, size, abrasive, particle size, hardness, structure, bonding agent, and linear speed.

1. Abrasive grade

Abrasive is the main component of the grinding wheel. It has high hardness, wear resistance, heat resistance and certain toughness to withstand the cutting heat and cutting force during grinding. At the same time, it should also have sharp corners to Sharp for grinding metal.

Abrasive grade | Subdivide the grade or grit range |

brown corundum(A) | A-Ceramic bonding abrasives A-P一High speed sanding belt (including machined sanding sheet) A-P2一cloth A-B Organic binder for abrasive tools A-S一Sandblasting and polishing |

white corundum (WA) | WA-Ceramic bonding abrasives WA-B -Organic binder for abrasive tools WA-P-Coated abrasives |

Monocrystalline corundum (SA) | The particle size ranges from F24 to F220. High hardness and toughness, strong cutting ability, |

microcrystalline corundum (MA) | The particle size range is divided into two levels: F4~F90 and F100~F220. High strength, greater toughness, suitable for For heavy-duty grinding, but also for precision grinding and even mirror grinding |

Black Aluminum Oxide (BA) | The particle size is divided into two levels: F220 coarse and F220 fine. Strong cutting force, high toughness, rigid and soft Economical, good wear resistance and high work efficiency. Mainly used in stainless steel, metal products, optical glass, etc. Sandblasting of high-end products, also used to manufacture resin grinding wheels, cutting discs, and emery cloth |

zirconia corundum (ZA) | ZA40--40%Zr2 ZA25--25%Zr2 ZA10-10%Zr2 The codes for bonded abrasives and coated abrasives are directly represented by their particle size marks; for refractory materials Codenamed R |

Chromium Corundum (PA) | 20PA- 0. 20%~0.45% Cr2O3 45 PA- 0. 45%~1.00% Cr2O3 100PA 1. 00%~2.00% Cr2()3 |

Semi-brittle corundum(FA) | Combining some advantages of brown and white corundum, it can be used in the production of ceramic abrades, resin abrades and coated abrades |

ceramic corundum (SG) | It is an alumina microcrystalline ceramic prepared by sol-gel process or sintered ceramic process |

black silicon carbide (C) | C-Ceramic bonding abrasives and abrasive belts C-B1-Organic binder for abrasive tools C-P- hand sanding belt |

green silicon carbide (GC) | GC-Ceramic bonding abrasives and abrasive belts GC-Bt- organic binder for abrasive tools GC-P--hand sanding belt |

Hybrid abrasive (AC) | A blend of related abrasives with their respective advantages and disadvantages |

cubic silicon carbide (SC) | β-SiC micropowders are used in the manufacture of high-grade whitetstones, fine grinding/polishing fluids, alternative diamond, |

cubic silicon carbide (BC) | Grit: F4~ F90、F100 ~ F220、F230~ F600和F800~ |

Diamond(D) | PDC-C- -≤40μm Diamond/carbide composite PDC-D- -≤5~ 100μm Diamond/carbide composite PCBN-C--≤40pm CBN/carbide composite |

Cubic boron nitride(CBN) | CBN100、CBN300--Black cubic boron nitride CBN200 、CBN400--Amber cubic boron nitride |

Abrasives types

corundum corundum

brown corundum

| white corundum | Single crystal corundum | microcrystalline corundum | Black corundum | zirconia corundum | Chromium Corundum | Semi-brittle corundum |

A | WA | SA | MA | BA | ZA | PA | FA |

ceramic corundum | black silicon carbide | green silicon carbide | Hybrid abrasive | cubic silicon carbide

| cubic silicon carbide | Diamond | Cubic boron nitride |

SG | C | GC | AC | SC | BC | D | CBN |

2. Grit

Grit refers to the size of the abrasive particles. Particle size is divided into two categories: abrasive grains and micro powder. Abrasives with particle sizes greater than 40 μm are called abrasive grains. Classified by the screening method, the particle size number is expressed by the number of holes per inch of the sieve through which the abrasive particles pass.

The grain size of the grinding wheel has a great influence on the roughness of the grinding surface and the grinding efficiency. The abrasive grains are coarse, the grinding depth is large, and the productivity is high, but the surface roughness value is large. On the contrary, the grinding depth is uniform and the surface roughness value is small. Therefore, when coarse grinding, generally choose coarse grit, and when fine grinding, choose fine grit. When grinding soft metals, coarse abrasive grains are often used; when grinding brittle and hard materials, finer abrasive grains are used.

Rough | |||||||||||

4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 | 16 | 20 | 22 | 24 |

Semi-finish | |||||||||||

30 | 36 | 40 | 46 | 54 | 60 | ||||||

Finish | |||||||||||

70 | 80 | 90 | 100 | 120 | 150 | 180 | 220 | ||||

Ultra- finish | |||||||||||

230 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | |

3. Hardness grade

The hardness of the grinding wheel refers to the difficulty of the abrasive grains falling off under the action of external force when the grinding wheel is working.

Hardness grade | Extreme soft | Very soft | Soft | Medium | Hard | Very hard | Super hard |

Code | A、B、C、D | E、F、G | H、J、K | L、M、N | P、Q、R、S | T | Y |

Structure Number | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

Abrasive ratio % | 62 | 60 | 58 | 56 | 54 | 52 | 50 | 48 | 46 | 44 | 42 | 40 | 38 | 36 | 34 |

Density | tightness | medium | Porosity | macro pore | |||||||||||

Usage Scale

| Heavy load, forming, | Outer circle, inner circle, none | Rough grinding and grinding workpiece with high toughness and low hardness, Suitable for grinding thin-walled, slender workpieces, or grinding wheels and workpieces Large contact surface and surface grinding, etc

| Non-ferrous metals, plastics, rubber and other non-metallic and heat-sensitive alloys | |||||||||||

Bond is the material that binds abrasive grains together to form an abrasive tool. The strength, impact resistance, heat resistance, and corrosion resistance of the grinding wheel mainly depend on the type and nature of the bond.

Bond type

V | R | RF | B |

Ceramic | resin | Reinforced rubber bond | Resin or other thermosetting organic bond |

BF | Mg | PL | |

Fiber reinforced resin bond | Plastic binder | Plastic binder | |

Conventional abrasive grinding wheel | Diamond grinding wheel | |||

inorganic bond |

organic bond

| Metal bond | ||

· ceramic bond

| magnesia bond | Resin bond | rubber bond

| |

---EDITOR: Doris Hu, Elio Song

---POST:Doris Hu

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]