M50 CNC PCD Grinding machine for grinding PCD PCBN tools

- With high efficiency and good edge quality

- High efficiency PCD machine and match with high-quality vitrified diamond grinding wheels

- 3 axes association can realize the fast automatic grinding of tool straight-line edge and radius edge grinding

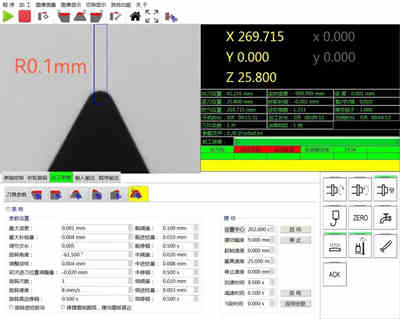

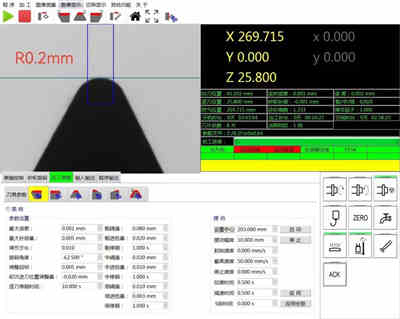

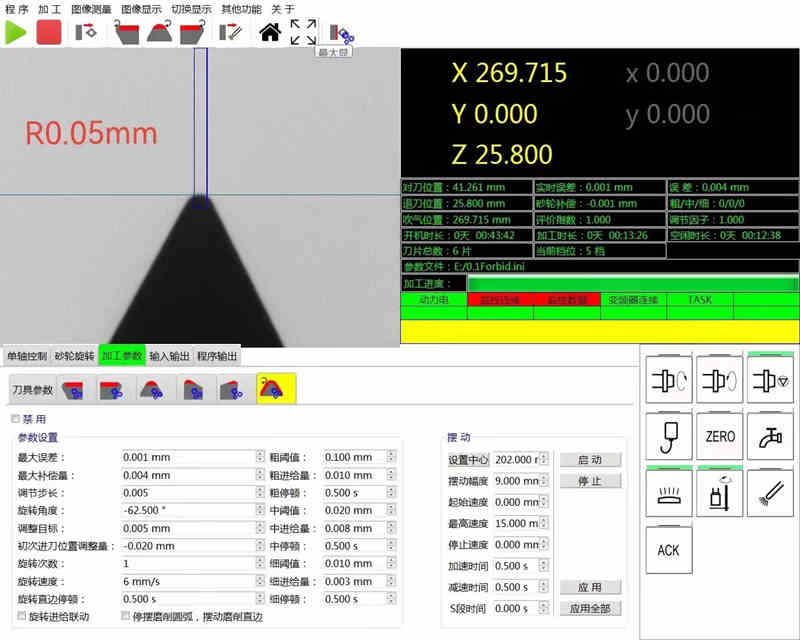

- Can achieve tool radius R0.03mm-R3 mm

M50CNC PCD/PCBN tool automatic grinding machine is M50 manual grinder CNC upgrade products, this machine has three CNC axis, and adopts a special CNC system based on image recognition technology to realize automatic grinding of straight edge and circular edge. Its structure and function can ensure the rapid grinding and high precision grinding demand of PCD/PCBN tools and welding brazed tools.

M50 CNC pcd machine is suitable for grinding and regrinding PCD, CBN, MCD, ceramics, carbide and HSS tools.

Characteristic of M50 PCD grinding machine

1, The main base parts are made of wear-resistant gray cast iron with optimized design, compact structure and stable performance.

2, After clamping, automatic machining of straight edge and arc edge is completed without manual intervention, with high grinding efficiency and good edge quality.

3, Using AC servo motor, precision ball screw, high strength rolling guide rail, harmonic reducer and other combination of transmission structure, can realize the spindle NC movement/swing, vertical axis NC rotation, tool rest NC feed and other automatic processing functions.

4, Equipped with high-definition image system, tool cleaning nozzle, fully sealed industrial vision backlight, automatic lens protection cover, pneumatic wheel dressing support and other devices.

5, The PCD/PCBN tool automatic machining control system based on image recognition is adopted with independent intellectual property rights.

M50 PCD Grinder Technical Parameters

Control System

Industrial computer | operating system | control software | ||||

I3/2G /500G (full seal) | Win7 Professional | KZW50 | ||||

CNC axis | ||||||

X axis (swing) | Y axis (rotation) | Z axis (feed) | ||||

travel | 280mm | 180° | 65mm | |||

speed | 0.001-50mm/s | 0.001-90° /s | 0.001-50mm/s | |||

resolution | 0.001mm | 0.001 | 0.001mm | |||

Manual shaft | ||||||

Table stroke | lens stroke | |||||

60x60mm | 50x50x50mm | |||||

Grinding wheel spindle | ||||||

speed | power | elevation | Swing distance | |||

Max. 4200 RPM | 2.2 kw | - 5-25 ° | Maximum 280 mm | |||

Imaging system | ||||||

Object distance | Pixel equivalent | Monitor size | Display resolution | |||

300 mm | 0.0041mm | 17" | 1600x900 | |||

Pneumatic system | ||||||

Clean air | Grindingwheel dresser | Air gun | Lens cover | |||

0.4-0.6 MPa | 0.4-0.6 MPa | 0.4-0.6 MPa | 0.2-0.3 MPa | |||

Machine tool | ||||||

The total power | Overall dimensions | The net weight | ||||

4.5 kw | 1500x1800x1900mm | 1300kg | ||||

Other | ||||||

Vitrified diamond wheel | Sic dressing wheel | Coolant tank | lubrication | |||

150 Χ 40 x 40 mm | 12.5 X25mm x80 | 65 | 14ml/24h | |||

Processing capacity | ||||||

Clamping tool holder size | Radius of fillet of tool tip | |||||

The largest 25 x25 mm | RO. 1-0.87 mm | |||||

The Standard Configuration

- The main part of machine

- Power supply and control system

- Work station

- Imaging system

- Pneumatic unit

- Work light and backlight

- Coolant tank

- Grinding wheel dresser

- Adjustable quick mounting fixture

- Standard accessories

- Technical documentation

M50 PCD Machine Processing Capacity

- Clamping tool holder size: maximum 25x25mm.

- Tip radius: R0.03mm - R3mm

Other inserts radius can be realized by customizing fixtures and installing grating scales

Suitable diamond grinding wheel for M50 CNC grinding machine

Standards specifications:D150*H40*T40*W15*X10

The choice of the width of the abrasives layer is based on the arc of the tool tip you want to grind. 1,2,3,4,5,10,15,20 all can be provided by Moresuperhard.

Applications of vitrified diamond grinding wheel

Vitrified bond diamond grinding wheels can be used for grinding PCD PCBN tools, CVD tools, MCD tools, carbide, ceramic tools, milling cutters, reamers, drills and grinding, etc.

Case of Regrinding R10 MCD cutting tools

MCD Tools chipping requirements after regrinding:2μm

Grinding procession:Rough regrinding and fine regrinding

1.Rough regrinding (W5 vitrified diamond grinding wheel )

It is necessary to take pictures under the microscope to see the shape and chipping of the tool If the chipping is too large, it needs to go through three grinding steps .Using vitrified diamond grinding wheel of W10, W5, W1.5.

When the customer's tool is rough grinding (the first tool of the day needs to be set), the Z axis is fixed at 10° Install the tool on the grinding machine, adjust the radius to 0.4, and adjust the elevation angle of the grinding wheel according to the angle of the tool. At this time, the grating ruler screen displays 9.6 Then adjust the lens barrel multiple to 1 according to the screen to see the left and right symmetry of the tool, then adjust the multiple to 5 times to see the size of the chipping, and finally adjust the tool retraction position according to the chipping situation and start grinding .

2.Fine grinding (Moresuperhard 10000# vitrified diamond grinding wheel)

Every Tools needs to be adjusted during fine grinding, because fine grinding has high requirements for chipping .According to the angle of the mcd cutting tools, the elevation angle of the grinding wheel can be adjusted, and it can be directly and automatically ground under normal circumstances. (The removal amount of fine grinding is 0.001mm per minute, and the time for fine grinding a mcd tool can be known according to the real-time error) After fine grinding, after inspection, the chipping of the tool meets the customer's requirements.

Semiconductor Industry Solutions

PCD & PCBN Tools Grinding Industry

Diamond Cutting Bruting Polishing

Add: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, 450001, Henan, China

Tel: +86-371-86545906

Phone / Whats App: +86 18339903057

E-mail: [email protected]